Composite gear provides an adequate strength to. So from these analysis results we conclude that the stress induced deformation and weight of the composite spur gear is less as compared to the cast steel spur gear.

Pdf Design And Analysis Of Composite Spur Gear

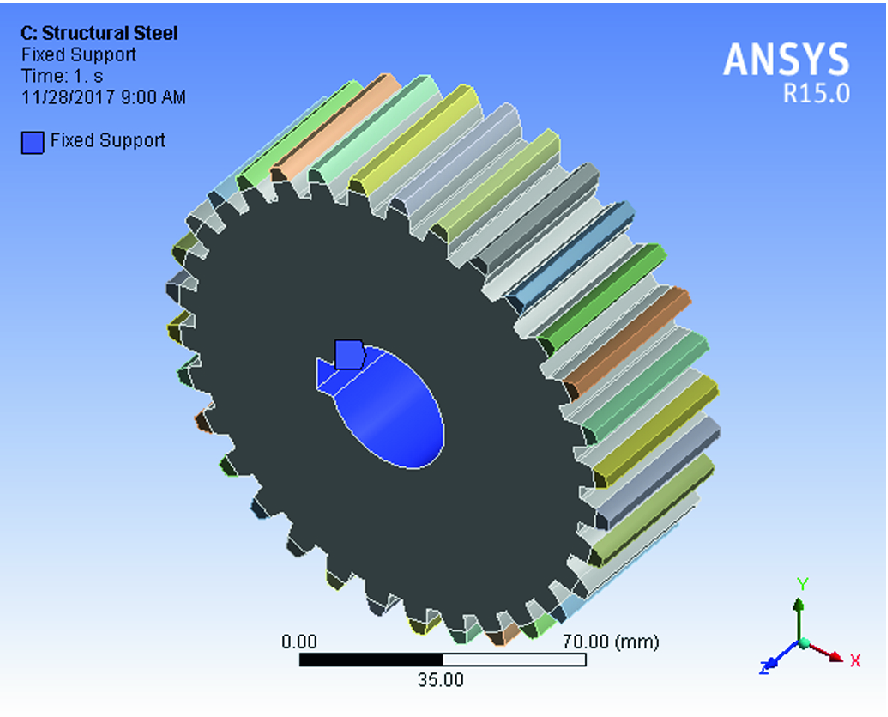

After Creating a model of spur gear analysis will be Carried out from gear made up cast steel and composite material in ANSYS Environment.

. In this chapter static finite element method is applied on the spur gear teeth for a. The weight reduction and stress distribution for cast steel and composite materials are studied. The hybrid gear was tested against an all-steel gear and against a mating hybrid gear.

To design the spur gear model using designs software and To study the structural analysis for existing and composite materials. Part design of Spur Gear B. 8312015 113243 AM.

8 represents the displacement analysis of the spur gear using composite material. Kavin Rajkumar et al. In their paper describes design and analysis of spur gear and it is proposed to substitute the metallic gears of sugarcane juice machine with polymer gears to reduce the weight and noise 10PBPawara et al 11 have given a detail comparison of metallic spur gear with the stir casted Al- SiC composite spur gear and an.

Design and Analysis of Composite Spur Gear SMahendran KMEazhil LSenthil Kumar Assistant Professor Mechanical Engineering SNS College of Engineering Abstract-To design the spur gear to study the weight reduction and stress distribution for cast steel and composite materialsGearing is one of the most critical components in a. Composite materials can be improved in properties over steel alloys and cast iron and hence these can be used as a better alternative for replacing a metallic gears. Finite Element Analysis of Spur Gear Bending stress of spur gear teeth is generally calculated by analytically and finite element method.

It is observed that when compared to the steel spur gears the percentage weight. Spur gear is one of the most commonly used component in power transmission between two parallel shafts they are widely used in. 2019 Design Analysis of Conventional and Composite Spur Gear Using Finite Element Method.

The composite web was bonded only to the inner and outer hexagonal features that were machined from an initially all-metallic aerospace quality spur gear. The widespread adoption of. From these analysis they got the stress values.

Spur gear using solid works software. Composite spur gears were designed fabricated and tested at NASA Glenn Research Center. DESIGN AND ANALYSIS OF SPUR GEAR BY USING PALM FIBRE AND E-GLASS COMPOSITE MATERIAL AND EVALUATE THE MECHANICAL PROPERTIES ARIKARANK1 AROCKIA DANIEL RAJS2 MANIGANDANS3 VIJAYASANKARC4 1234 Department of Mechanical Engineering Excel College of Engineering and Technology Pallakapalayam ----------Abstract - Hybrid.

The finite element model of spur gear is developed with the assistance of the Ansys software. Solid Model of Spur Gear Fig. Shinde S P Nikam A and Mulla T S 2012 Static Analysis of Spur Gear Using Finite Element Analysis IOSR Journal of Mechanical and Civil Engineering IOSR-JMCE pp.

An APDL gear model has been developed for the design evaluation and comparison study. Analysis of composite spur gear for contact stress. Finally compare and analyzing the spur gear using ansys software.

Design and analysis of composite spur gears using finite element method S Rajeshkumar and R Manoharan School of Mechanical Engineering VIT University Vellore-632014 Tamil Nadu India. Steel spur gear can be replaced by GF 30 PEEKcomposite spur gear due to its high strength 5. In that they studied weight reduction and stress distribution of spur gear for cast steel and composite materials.

Eds Smart Technologies for Energy Environment and Sustainable Development. In this study the parametric design and contact analysis of composite spur gears are investigated numerically. 2-D Part design of Spur Gear Fig.

Design the spur gear to study the weight reduction and stress distribution for cast steel and composite materials and to design the spur gear model using Creo software. MAE 342 Dynamics of Machines 2 Idealized Spur Gears. Volume I Issue VI November 2014 IJRSI ISSN 2321 - 2705 Design and Analysis of Composite Spur Gear SMahendran KMEazhil LSenthil Kumar Assistant Professor Mechanical Engineering SNS College of Engineering Abstract-To design the spur gear to study the weight reduction When pinion is the driver it results in step down drive in and stress distribution for.

It is observed that stress is reduced by nearly 25 due to the use of composite material 6. To Design and draw a spur gear and Analyse the stress distribution of the cast steel and the composite material. DESIGN AND ANALYSIS OF BANANA FIBER REINFORCED POLYMER SPUR GEAR MANUFACTURED BY GEAR HOBBING PROCESS SSivaganesan1 SJoseph irudaya raja2 CGnanavel 3 AParthiban4 Email id.

Kolhe M Labhasetwar P Suryawanshi H. In this study the parametric design and contact analysis of composite spur gears are investigated numerically. DEVENDRA SINGH In this paper modeled the spur gear and study about gear drive design and analysis is carried.

The maximum displacement for the composite material of spur gear is 0000307911 mm. So Composite materials are capable of using in automobile vehicle gear boxes up to 15KN in the application of Tata super ace model instead of existing cast steel gears with. Shanavas S 2013 Stress Analysis of Composite Spur Gear International Journal of Engineering Research Technology IJERT ISSN.

Download high-res image 91KB. DESIGN AND ANALYSIS OF SPUR GEAR BY. Have proposed design and analysis of composite spur gear.

2014 the pressure in the gear tooth was analysed to decrease the stress in the gear tooth. USING BLACK FIBER E-GLASS FIBER AND CARBON FIBER WITH ISOPOLYMER ABSTRACT Hybrid Composite material have evoked a keen interest in recent times for potential applications in aerospace and automotive industries owing to their superior strength to weight ratio and temperature resistance. The maximum strain produced for the spur gear in composite material is 17621 10-5 at 6239th element.

Gajhas MS Keche AJ. Lecture Notes on Multidisciplinary Industrial Engineering. A study of spur gear by ANSYS is used.

In this study each design factor such has stress distributions strain and deformation are considered to compare composite gear with steel and polymer gears. Vigithra has presented design and analysis of Nano composite spur gear. Microsoft PowerPoint - Lecture 3-Spur_gearspptx Author.

In order to reduce the stress in the spur gear contact tooth a Finite Element model with an. Performed the contact analysis of spur gears to find the stress distribution between gear teeth.

Pdf Analysis Of Composite Material Spur Gear Under Static Loading Condition

Pdf Design And Analysis Of Composite Spur Gears Using Finite Element Method

Pdf Design And Analysis Of Composite Spur Gear

Design Analysis Of Conventional And Composite Spur Gear Using Finite Element Method Springerlink

Pdf Design And Analysis Of Composite Spur Gear Research And Scientific Innovation Society Rsis International Academia Edu

Pdf Analysis Of Composite Material Spur Gear Under Static Loading Condition Semantic Scholar

Design Analysis Of Conventional And Composite Spur Gear Using Finite Element Method Springerlink

0 comments

Post a Comment